Asphalt shingles are the one of the most commonly used roofing covering for steep slope roofing. They are generally composed of asphalt, fillers, a reinforcing mat and granule surfacing. Asphalt shingles are available in a variety of shapes, colours and thicknesses but the two main types are:

- Three-tab self-sealing strip shingles

- Architectural (composite) or laminated shingles

All asphalt shingles, surfaced with mineral granules must be manufactured to meet the standards of CSA A123.5 Asphalt shingles made from glass felt and surfaced with mineral granules which should be designated on the packaging and manufacturer data sheets.

Mineral granules are embedded in the asphalt coating on the top surface of the shingle. Because of the asphalt and type of reinforcement the shingle may be flexible or brittle, depending on the temperature. The best temperature to work with shingles is between 4.4°C to 27°C (40°F to 80°F). In lower temperatures, shingles become brittle and harder to cut and at higher temperatures a soft shingle can be easily damaged and scuffed. Depending on weather conditions, additional precautions may be required when applying asphalt shingles.

Shingles need to be flexible so as to be woven into valleys and bent over ridges, but the flexibility can have drawbacks as it allows the shingles to assume the shape of the material that they are laid over. When reroofing over an existing roof, this could affect the overall look of the roof especially if the old roof was rough and uneven. Flexibility can also cause shingles to blow off in a warm wind or be damaged by a cold wind.

Shingles are installed to a nailable roof deck typically consisting of wood: plywood or oriented strandboard (OSB) panels that are fastened directly to the structural framing.

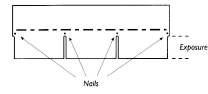

A standard 3-tab shingle is 1000 mm (39 ⅜ in) long and 337 mm (13 ¼ in) wide. The exposure (the part of the shingle that is exposed to view) is usually 143 mm (5 ½ in) or any dimension that provides a minimum of a 50 mm (2 in) head lap under the third course.

A standard 3-tab shingle is 1000 mm (39 ⅜ in) long and 337 mm (13 ¼ in) wide. The exposure (the part of the shingle that is exposed to view) is usually 143 mm (5 ½ in) or any dimension that provides a minimum of a 50 mm (2 in) head lap under the third course.

Asphalt shingles have a tabbing strip which, when activated by the heat of the sun, helps bond the shingles together to provide a weather tight bond. Hand tabbing may be required in windy or cold weather conditions.

The weight of an asphalt shingle can vary between 10 kg/m2 to 18.5 kg/m2 (210 lb/square to 380 lb/square), depending on the type of material and the number of plies required in the coverage.

Normally an asphalt shingle roof has a double coverage of shingles. To be double coverage, the shingles must overlap each other by slightly more than half, providing two layers of shingles over the entire roof area. By overlapping more than half there is a small area that will be three layers thick. This is called the headlap. Most of the new shingles with a shake appearance are double coverage, and a few provide triple coverage.