Wood shakes and wood shingles are natural products. Wood shakes and wood shingles are used mainly when the designer of the building wants to provide an element of natural beauty to the premises. The major advantage is their durability against the elements which leads to a longer life span. They are a durable covering which can be applied from a minimum slope of 1:4 to a vertical wall. The major disadvantage is that, because they are a wood product, they are more flammable. Also, their rigidness makes them harder to work with on domed or concave shaped roof decks.

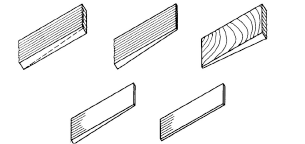

Shakes are split on face to provide a textured surface. Shingles are sawn on both sides to provide a smooth uniform surface.

Wood Shakes

Wood shakes are typically cut in three lengths – 400 mm, 450 mm, and 600 mm (16 in, 18 in, and 24 in). There are also three types that are used in roofing:

- Hand split-resawn

- Straight split

- Taper split

Shakes that are 400 mm (16 in) in length are only used as starter-finish shakes, for application at ridges and eaves as the starter row and hips. For application over the main roof, 450 mm (18 in) or 600 mm (24 in) lengths must be used.

Wood shakes can be cut from any species of wood (cedar, pine, etc.) that has a fairly straight grain. However, in Canada the two most common woods used in roofing is Western Red Cedar and Eastern White Cedar.

Wood shakes are packed in bundles 450 mm (18 in) wide, with nine (9) courses per bundle on each side of the band. The minimum recommended pitch for hand split shakes is 4:12 or 1:3.

The first step in the production of wood shakes is the selection of the most suitable logs. The logs are then stripped of the bark and the sapwood is removed and the logs are cut into lengths from 400 mm to 600 mm (16 in to 24 in). If the sapwood is left on, these shakes would not be considered No.1 quality. These log lengths are then split by hand or machine into wedge shaped pieces.

Should the grain not be straight or a branch has created a knot in the wood, the wood may be thrown away or possibly used in a lower grade shake. The bolt is then split to form shakes with either a vertical or edge grain. The bolt can be split from the same each time. This will produce a shake of equal thickness from end to end, usually about 9.5 mm (3/8 in) called a straight split or a blank about 32 mm (1 1/4 in) thick from which two shakes can be cut using a band saw (called hand split and resawn). The split side of this shake is installed face up on the roof. If the shingle bolt is reversed each time it is split, the shake produced will have a slight taper (called a taper split).

Hand Split Resawn

These shakes have a butt thickness of 12 mm to 12.7 mm (7/16 to 1/2 in) and 12.7 mm to 19 mm (1/2 in to ¾ in). They are cut in lengths of 400 mm, 450 mm, and 600 mm (16 in, 18 in and 24 in).

Straight Split

These shakes have a thickness of 9.5 mm x 450 mm and 600 mm (3/8 in x 18 in and 24 in). Thickness is constant throughout the length but may vary due to splitting across the width. These shakes vary in width from 100 mm to 350 mm (4 in to 14 in).

Taper Split

The shake length 600 mm (24 in), butt thickness 12.7 mm to 15.9 mm (1/2 to 5/8 in). The thickness of the top of the shake will depend on the grain, but it is usually more than hand split resawn shakes.

Wood Shingles

Wood shingles are graded according to their quality of wood and grain, No. 1 being the premium grade, while No. 4 is the utility grade used for starter courses. They are packed in straight courses in regulation frames 508 mm (20 in) wide and not less than 480 mm (19 in) long. 400 mm (16 in) shingles are packed 20/20 which means that there are 20 courses in each side of the bundle.

A good wood shingle roof is never less than three layers thick. Consequently, the exposure of any given shingle must be slightly less than one third of its length. The exposure will decrease as the slope of the roof decreases. Tables giving the maximum recommended exposure for a given slope are available from the Cedar Shake and Shingle Bureau.

The eave of the roof will require a double course of shingles. With wood shingles one square will provide about 240 lineal feet of double course. Also, for every 100 feet of valley allow one square of shingles.