The basic roofing tools used by the roofer include the following.

Spud Bar

![]() The spud bar is used to remove the flood coat and gravel from the surface of a built-up roof (BUR) membrane (spudding) to allow access to the membrane plies. The 100 – 200 mm (4 – 8 in) blade can be removed and replaced as they become dull, so no sharpening is required. The spud bar should not be used as a pry bar as they bend easily and the spud blade may break. Slide the spud bar back and forth over the membrane to remove the flood coat. Do not jab it, as the sharp blade will puncture the membrane.

The spud bar is used to remove the flood coat and gravel from the surface of a built-up roof (BUR) membrane (spudding) to allow access to the membrane plies. The 100 – 200 mm (4 – 8 in) blade can be removed and replaced as they become dull, so no sharpening is required. The spud bar should not be used as a pry bar as they bend easily and the spud blade may break. Slide the spud bar back and forth over the membrane to remove the flood coat. Do not jab it, as the sharp blade will puncture the membrane.

Spade

A spade has many uses on a roof. It can be used to tear off both built-up and steep roofing, and it can also be used to remove the gravel surface of a built-up roof much like a spud bar. The spade can be used to do most of the prying during a tear-off but should not be used for heavy prying as the handle or blade could break. The blade of a spade becomes round after heavy use and can be squared again with a grind wheel or grinder.

A spade has many uses on a roof. It can be used to tear off both built-up and steep roofing, and it can also be used to remove the gravel surface of a built-up roof much like a spud bar. The spade can be used to do most of the prying during a tear-off but should not be used for heavy prying as the handle or blade could break. The blade of a spade becomes round after heavy use and can be squared again with a grind wheel or grinder.

Pinch Bar/Pry-Bar

There are many variations of these bars but most have a heavy long handle to use for leverage and a heavy wedged shaped end. This bar can be used for heavy prying and can be useful in removing wood cant strips, metal and lead flashings, curbs and sleepers.

Wheel Barrow

Wheelbarrows are used for general clean up and for moving material and equipment around the roof. It is recommended that a dual wheeled wheelbarrow be used on roof surfaces as this will help distribute the weight over a larger area and reduce the chance of a membrane puncture.

Wheelbarrows are used for general clean up and for moving material and equipment around the roof. It is recommended that a dual wheeled wheelbarrow be used on roof surfaces as this will help distribute the weight over a larger area and reduce the chance of a membrane puncture.

Push Brooms

Push Brooms

Push brooms are very useful in helping sweep up heavy gravel and debris and by kettle operators for keeping the kettle area clean. They can also be used to move ponded water to drains or scuppers. The push broom can also be used to broom roofing felts into hot asphalt.

Corn Broom

Corn brooms are used to remove small debris, gravel, dust, water etc.

Scoop Shovel

Scoop shovels are used to shovel and apply gravel, remove debris etc.

Pouring Can

Pouring cans are used to apply the asphalt at the flood coat and gravel stage of the application. They are usually very effective on smaller roofs where gravel must be applied by hand. They can also be used to apply felts in the “pour and roll method”, although seldom used in Canada.

Dipper (or ladle)

Dipper (or ladle)

Dippers are used to apply hot asphalt to areas that are difficult to reach with a pouring can, or a hot application for the flood coat and gravel. They have a handle with a dipper at the end which is dipped into the mop buggy and the asphalt then poured over the roof membrane.

Caulking Gun

Caulking Gun

Caulking guns are available in various sizes and with different nozzles, use disposable cartridges or filled with bulk caulking.

Staplers

Tacker Stapler

A tacker stapler is a spring-driven tool used for driving staples into

various materials. There are many different styles available from manufacturers.

To operate the tacker, you must insert your fingers into the hand grip and, while holding the stapler firmly against the work squeeze the trigger.

Some of the many uses of the tacker are:

- Fastening building paper to exterior walls or decks

- Fastening vapour retarder

- Fastening ceiling tiles

- Fastening weather stripping

- Fastening some types of insulation

The means of loading the tool with staples may differ from style to style. Refer to manufacturer’s instructions how to properly load.

Hammer Stapler

The hammer stapler is a mechanically operated tool that is designed to be used much like a hammer.

The hammer stapler is a mechanically operated tool that is designed to be used much like a hammer.

To operate a hammer stapler, you must grasp the handle and strike the head of the stapler against the work. Insufficient force will result in inadequate fastening. Too much force will result in damage to the work or the tool.

The hammer stapler may be used for most of the same jobs as the tacker, with the exception of ceiling tile work. The force to the blow and the degree of accuracy required cause problems with delicate tile surfaces. The hammer stapler allows you to reach hard-to-get-at places and is also used to fasten felts (much faster than nailing). Check the manufacturer’s instructions on how to properly load a hammer stapler.

Staples

There are various kinds and sizes of staples being used in spring-driven staplers. The kind and size depend on:

- The particular work being done, which will determine the type of point and leg length to use.

- The style and brand name of stapler being used, which will determine the shape and crown width of the staple.

Two common types of staple points are chisel and divergent. Chisel points help to keep the legs of the staple parallel to the depth of the entire length of the leg. Divergent points cause the staple legs to bend (diverge) after penetration thus putting the staple legs under tension and increasing the holding power.

Files

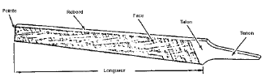

A file is a piece of hardened, high grade steel with slanting rows of teeth chiselled into its surface.

A file is a piece of hardened, high grade steel with slanting rows of teeth chiselled into its surface.

These teeth cut and remove small amounts of material from a workpiece. Filing is most often used to smooth metal surfaces by removing sharp edges and burrs from machined parts. Files will not cut hardened steel or other materials harder than the file materials.

Safety Rules for Files

- Never use a file without a handle on the tang. The tang is sharp and can cause severe hand injuries.

- Whenever possible, the part to be filed should be clamped securely in a vice.

- Files should never be used as pry bars. The file metal is very brittle and may break causing serious injury.

- Never hammer on a file. Since it is very brittle, it may shatter and send metal fragments flying in every direction, which may cause serious injury to yourself and others.

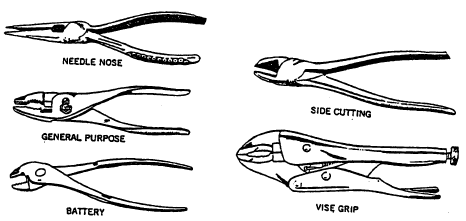

Metal Pliers

Pliers are clamping tools used for holding, cutting, and bending work. They come in a variety of styles, shapes and sizes. As well, there are various applications for their use.

Safety Rules for Pliers

- Never use pliers as hammers.

- Always use pliers for their intended use only, holding or gripping objects.

- Never use pliers as a substitute for wrenches, for loosening or tightening nuts or bolts.

- Avoid using pliers on hardened surfaces. This damages teeth, and they will lose their gripping quality.

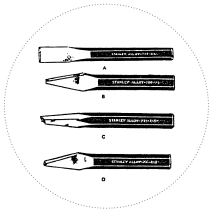

Chisels

Chisels

Chisels are made from heat-treated steels. They come in various styles, shapes and sizes. The most common are the flat, diamond point, round nose and cape chisel.

They are considered the simplest of cutting tools, using a wedging action to cut and chip metal.

Punches

Punches

The most common punches are the prick punch, center punch and pin punches.

They are used for marking the center of holes for drilling, removing of pins and aligning of mating parts.

Safety Rules for Chisels and Punches

- Always use eye protection.

- Never use a punch or chisel with a chipped or mushroomed head. To prevent personal injury from flying chips, the mushroomed head should be ground off. Heavy hammer blows will mushroom the punch’s head.

- Always use a punch handle or holder wherever possible.

2.1.2.1 Hot Carriers and Equipment

In built-up roofing there is a variety of equipment used to transport or carry hot asphalt, commonly referred to as “hot bitumen”. This includes hot carriers, hot dispensers, felt layers, hot coater-mopper and mop carts.

All of this equipment is easily damaged while being transported to and from the job sites. If this equipment were made of heavier material, it would become too difficult for the operator to move when loaded. Therefore, most of this equipment is very light and can be damaged easily when being loaded or unloaded from trucks, or when hoisted to the roof.

Safety Rules for Hot Carriers

- NEVER throw on-deck equipment to the ground from the truck. Always lower them easily so that there is no hard impact.

- NEVER load heavy material on top of the on-deck equipment. That kind of abuse will cause bent axles which make the asphalt carrier very difficult to steer in a straight line when the operator is using it for applying material. Sharp impacts will also cause leaks as well as bent valves in the dispenser unit.

- NEVER leave deck equipment unattended on a sloping roof.

- NEVER raise or lower a “hot bitumen” carrier to or from roof unless it is cold and empty.

- NEVER place hot material into a “hot bitumen” carrier in such a way as to cause a splash. This could cause a serious burn to you or a fellow worker in the vicinity.

- NEVER step in asphalt as it is hot and slippery. A fall can cause serious injury.

- “Hot bitumen” should NEVER be closer than 75 mm (3 in) from the top of the container.

- ALWAYS turn over “hot bitumen” carriers every night to prevent rain or moisture from getting into the carrier. If hot asphalt is placed into a carrier that has water in it, a serious burn accident could result.

- ALWAYS check “hot bitumen” carriers every morning to be certain that they do not have any water in them.

The entire working area should be clear of debris that could cause an asphalt carrier to tip over if struck while moving. Mops should never be left lying on the roof area being worked because it is too easy to trip over the handles.

Hot Luggers or Hot Buggies

Hot Luggers or Hot Buggies

Hot luggers are typically enclosed tanks with a fill opening, vent, and pouring spigot that are used to transport hot bitumen from the roof edge to the point of application. Hot luggers are made in two sizes, 114 and 190 litres (30 and 50 gallon) carriers. The hot material is usually emptied into a mop cart or into felt layers or hot spreaders.

Remember, the danger of fire or explosion resulting in serious damage to property and human injury is not left behind on the ground with the kettle. Everywhere hot bitumen is present, the danger exists. Treat on-deck equipment and the hot bitumen it holds with respect.

It is important to be certain that the hot lugger vent is clear of debris and not covered over with any hardened material. Serious burns can result if the vent is not open. The material can erupt back through the fill opening and spill over the operator if the vent is clogged.

When filling a hot lugger for the first time in the morning, be certain that there is no water in the tank, and always stand clear of the opening.

NEVER place hot material into a hot bitumen carrier so as to cause a splash. This can cause a serious burn to you or fellow workers in the vicinity.

Hot luggers must be level when filling or you can trap fumes which can then ignite.

Buckets

Many different kinds of buckets are used in the roofing industry, but those listed here are the most common types. A general safety precaution for the use of any bucket is to be sure that it is empty of water and moisture before using it. Water in the bucket may cause hot bitumen to boil over.

Many different kinds of buckets are used in the roofing industry, but those listed here are the most common types. A general safety precaution for the use of any bucket is to be sure that it is empty of water and moisture before using it. Water in the bucket may cause hot bitumen to boil over.

A special bucket called a “crack filler” is used to fill expansion joints, cracks or joints in cement with hot asphalt.

A sprinkler pot is used for sprinkle-pouring of bitumen on the surface of built-up roofs before gravelling or similar jobs (pour pail).

A roofer’s bucket is made of 24-gauge steel. Its round iron carrying handle rests off the top to engage a hoisting hook. In some cases, this bucket is insulated to maintain the contents at the proper temperature.

A roofer’s bucket is made of 24-gauge steel. Its round iron carrying handle rests off the top to engage a hoisting hook. In some cases, this bucket is insulated to maintain the contents at the proper temperature.

A lightweight dipper or ladle is used for hot tar or asphalt. It has a long aluminium or hardwood handle.

All buckets should be equipped with a safety handle.

Carts

Carts are used for various hauling jobs, such as transporting rolls of felt and insulation and pails of hot bitumen. Mop carts, some designed with removable trays to carry hot bitumen, are in wide use on larger roof jobs today.

The highboy is a drum mounted on a frame equipped with wheels so it can be moved around the roof easily to deliver hot bitumen where needed. It is used on large jobs where the hot bitumen is pumped to the roof and into the drum.

Mops

Mops

Mops are made with various size heads of fibreglass or cotton. Cotton mops hold larger quantities of asphalt than fibreglass mops of the same size, but fibreglass mops are more durable and easier to drain. Both aluminium and wood are used for the handles.

Roller Mops

The roller mop is used for applying hot asphalt in the waterproofing of walls and the like. A similar roller with short strands is used for applying roof coatings.

SAFETY PRECAUTION

Be sure mops are cleaned, fanned out, and placed where they will not become fire hazards through spontaneous combustion.

NEVER LEAVE A MOP ON A ROOF OVERNIGHT!

Squeegees

Squeegees

Another piece of common roofing equipment is the squeegee. It is generally used in waterproofing for spreading emulsions and for coatings. It is also used for applying a thin glaze coat of asphalt on completed sections of roofing membrane for temporary protection, and to remove water in preparation for roofing.

Pushers

Pushers are tools used to spread gravel onto the pour coat of hot bitumen. They are usually made of cast aluminium and have long aluminium handles.