Whenever you are required to work at an elevated area for any more than a short period of time, scaffolding will make the work much easier and safer than working from a ladder.

Steel Scaffolding

Tubular steel scaffolding is widely used as a working platform primarily because it is strong; lightweight; easily assembled and dismantled; and portable as a prefabricated unit.

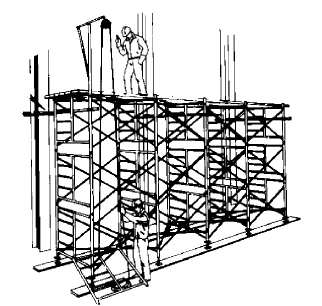

The steel scaffolding has two basic parts: the end frame and the cross brace. By assembling two end frames and two cross braces, we get one basic section.

These sections can be extended upward by assembling another basic unit on top of the first, using coupler-pins to align and secure one directly over the other.

When a section of scaffolding which is more than one unit high is to be transported, the end frames must be secured to each other. This can be accomplished by inserting pins or bolts through the end frames and the coupler-pins. If the scaffolding is to remain stationary, the pins or bolts need not be installed through the coupler-pins.

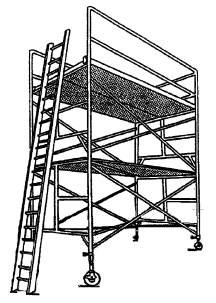

Casters can be placed into the legs of the lower end frame to make the scaffold into a rolling scaffold. When casters are used on this type of scaffolding, the casters must be installed so that they cannot fall out should one end of the scaffold be lifted from the floor. The wheels must also have effective locking devices (brakes) which are engaged when workers are over 3 m (10 ft) above floor level.

When steel scaffolding is fitted with casters, it must also be fitted with a sway brace (a horizontal cross brace) to provide rigidity to the unit.

A rolling scaffold must not exceed three times the smaller dimension of its base. A worker must not remain on a rolling scaffold while it is being moved if the platform height exceeds twice the smaller dimension of its base.

The floor or surface on which the scaffold is moved must be within three degrees of level, and must be free from pits, depressions, or obstructions.

When steel scaffolding is erected in long, high units, it must be secured to the building structure at 6 m (20 ft) intervals horizontally and every 4.5 m (15 ft) vertically.

Long sections are simply made by assembling units side by side and connecting them with cross braces.

Whenever scaffolding is erected it should be level and on firm ground. To prevent the legs from sinking, mud sill no less than 38 mm x 235 mm x 250 mm (1 ½ in x 9 ¼ in x 10 in) long should be placed under each vertical leg of the scaffold. Base plates should be used to distribute the weight of the scaffold over a larger area of the mud sill. If the terrain is uneven, screw jacks or an adjustable base jack should be used to level the scaffold.

NEVER USE BRICKS, PALLETS, BOXES, OR BUILDING BLOCKS TO LEVEL THE BASE OF A SCAFFOLD!

Whenever a work platform is more than 3 m (10 ft) above grade, guardrails and toeboards are required on all open sides of the scaffold platform. The guardrail unit should consist of a top rail, a midrail and a toeboard. The top rail is placed 1070 mm (42 in) above the platform; the midrail is set half way between the top rail and the toeboard should be approximately 100 mm (4 in) high. The clearance between the bottom of the toeboard and the platform should not be more than 12.7 mm (1/2 in).

Whenever a work platform is more than 3 m (10 ft) above grade, guardrails and toeboards are required on all open sides of the scaffold platform. The guardrail unit should consist of a top rail, a midrail and a toeboard. The top rail is placed 1070 mm (42 in) above the platform; the midrail is set half way between the top rail and the toeboard should be approximately 100 mm (4 in) high. The clearance between the bottom of the toeboard and the platform should not be more than 12.7 mm (1/2 in).

Guardrails can be erected at the top of the steel scaffolding with specially made components consisting of guardrail posts and metal guardrails. If guardrail components are not available, an additional section of scaffolding can be added for height and wooden guardrails attached to this section.

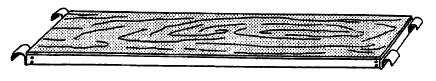

The planks used for the work platform can be specially made planks manufactured to match the steel scaffolding and hooks onto the horizontal bars of the end of frames. Planks are typically 508 mm (20 in) wide. Lumber planks can also be used. Lumber scaffold planks cannot be smaller than 38 mm x 240 mm (1 ½ in x 9 1/2 in) in size and must meet provincial regulations for Select Structural Scaffold Lumber.

Scaffold material should be inspected before every use. Materials that are found to be defective, cracked, warped, or corroded should be removed from use and replaced immediately.

Scaffold planks must extend not less than 150 mm (6 in), and not more than 300 mm (12 in) beyond the supporting members.

Scaffold comes with different depths from front guardrails to back guardrails, starting from 508 mm (20 in). The most common, though, is 1270 mm (50 in) deep. Regardless of the depth, there are two important rules that apply to the creation of platforms on a scaffold. First, no platform is to be narrower than 508 mm (20 in), and second, you must never leave a horizontal space or more than 250 mm (10 in) between the edges of the platform and the guardrails.

REMEMBER: Knowing how to safely assemble and use steel scaffolding is no guarantee that you will not have an accident while working on one. Whenever you are erecting or working on scaffolding, you must be alert. You have to be aware of where you can safely step and what you can hang onto, if you want to be able to climb off rather than fall off.