When under construction, the rooftop can be a noisy environment. Mechanical equipment, such as roof cutters, drills, saws, gas and diesel hoists, and firing propane torches can produce noise that may be harmful to hearing. Many different sources of noise account for the overall noise. This means that the actual level of noise a worker is exposed to may be much greater than it would be if they were exposed to only one source of noise.

When under construction, the rooftop can be a noisy environment. Mechanical equipment, such as roof cutters, drills, saws, gas and diesel hoists, and firing propane torches can produce noise that may be harmful to hearing. Many different sources of noise account for the overall noise. This means that the actual level of noise a worker is exposed to may be much greater than it would be if they were exposed to only one source of noise.

Temporary or permanent hearing loss can result from exposure to high levels of noise. A person suffering hearing loss may not notice it until it is too late. For this reason, noise prevention and control procedures are based on the potential for hearing loss and not the individual’s perception of what is too loud and noisy. Waiting for personal discomfort before taking preventive measures may be too late to avoid a permanent noise-induced hearing loss.

The surest method of preventing occupational deafness is to reduce noise at the source by engineering methods. However, in certain workplace conditions, there is very little or nothing one can do to reduce noise at the source. In such workplaces, workers need to wear hearing protection to reduce the amount of noise.

Measuring Sound

Measuring the sound levels workers are exposed to throughout an entire working day can determine if the noise levels are a hazard. Decibels (dB) measure the intensity of sound. The scale runs from the faintest sound the human ear can detect, which is labeled 0 dB, to more than 180 dB, the noise at a rocket pad during launch. Most experts agree that continual exposure to more than 85 decibels is dangerous. A jet engine has a noise level of 149 dB and even brief exposure can cause pain and permanently injure unprotected ears.

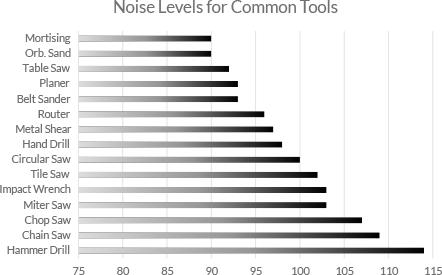

The graphic below, from the U.S. Occupational Safety and Health Administration, lists the typical noise levels of equipment commonly found on roofing and construction sites.

You will often see noise levels given in dBA. The A signifies weighted sound levels. Measurements in dBA are decibel scale readings that have been adjusted to take into account the varying sensitivity of the human ear to different frequencies of sound. The main effect is that low and very high frequencies are given less weight than on the standard decibel scale. Most noise limits are specified in terms of dBA, based on the belief that it is a better measure of the risk of noise induced hearing loss. If the noise or sound level at the workplace exceeds 85 decibels (A-weighted) or dB(A) hearing protection should be worn.

It is important to evaluate the exposure to noise based on an entire work day and not on an intermittent or sporadic basis. Evaluation is based on eight-hour noise exposure, not a spot or area measurement. This takes into account that exposure to noise may not be continuous. For example, a burner on a kettle fully open may produce a noise level of 100 dBA, but because the kettle may not be operating for the whole day, the kettle operator may be exposed to an average of 90 dBA over an eight-hour shift.

Types of hearing protection

There are three main types of hearing protection available as follows.

Ear plugs, which are inserted in the ear to block noise from entering the ear canal, can be pre-formed and molded to fit the ear, or made of a material, such as expanded foam, which takes the shape of the ear canal. They are sold as disposable products or reusable plugs. They can also be custom molded to fit the individual.

Ear plugs, which are inserted in the ear to block noise from entering the ear canal, can be pre-formed and molded to fit the ear, or made of a material, such as expanded foam, which takes the shape of the ear canal. They are sold as disposable products or reusable plugs. They can also be custom molded to fit the individual.- Semi-insert ear plugs consist of two ear plugs held over the ends of the ear canal by a rigid headband.

Ear muffs consist of sound-attenuating material and soft ear cushions seated in hard outer cups held together by a headband.

Ear muffs consist of sound-attenuating material and soft ear cushions seated in hard outer cups held together by a headband.

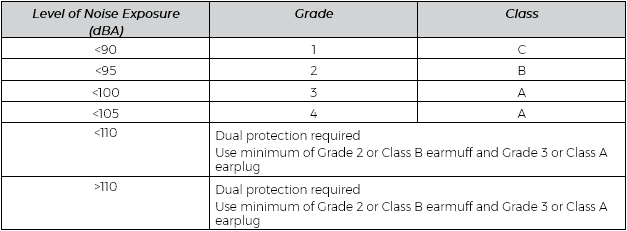

CSA Z94.2 Hearing Protection Devices – Performance, selection, care and use, classifies hearing protectors as A, B, and C or Grades 1, 2, 3, or 4 based on the level of protection they provide, with Grade 4 Class A providing higher protection than Grade 1 or Class C protectors if worn properly.

The effectiveness of hearing protection is reduced greatly if the hearing protectors do not fit properly or if they are worn only part time during periods of noise exposure. To maintain their effectiveness, they should never be modified. Radio headsets are not substitutes for hearing protectors.

Always choose the hearing protection that is correct for the job or contact the organization responsible for occupational health and safety in your province or territory for information on the correct hearing protection you need.

The following table that is based on CSA Z94.2 and lists the recommended hearing protection class for the anticipated level of noise exposure.

The choice of hearing protectors is a very personal one and depends on a number of factors including level of noise, comfort, and the suitability of the hearing protector for both the worker and his environment. Most importantly, the hearing protector should provide the desired noise reduction. It is best, where protectors must be used, to provide a choice of a number of different types to choose from.

If the noise exposure is intermittent, ear muffs are more desirable, since it may be inconvenient to remove and reinsert earplugs.