The single most important precaution in hoisting and rigging is to determine the weight of the load before attempting to lift it. At the same time, riggers must also determine the available capacity of the equipment being used.

- Counterweights must be of sufficient weight and secured to hoist. Never use roofing material as a counterweight.

- A hoist must never be set-up over a doorway or near power lines.

- Before lifting ensure the load is stable, secure and ground workers are clear of the area. Hoist material vertically only and never exceed the manufacturer’s rated capacity.

- In windy conditions, use a tagline to prevent load from swaying.

- Hoists must only be used for vertical lifting. Never use them for dragging or scooping which could pull them off the roof.

You must always be aware of safety hazards from lifting and hoisting loads to and from a roof.

Always rig the load so that it is stable (unless the center of gravity of the load is below the hook, the load will shift). Make allowances for any unknown factors. In addition, riggers must be aware of the following:

- Common hazards

- Factors that reduce capacity

- Inspection and use of slings

- Safe practices in rigging, lifting, and landing loads

1.8.1.1 Factors Affecting Hoisting

- Working Load Limit (WLL) not known

Do not assume. Know the working load limits of the equipment being used and never exceed these limits. - Defective Components

Examine all hardware, equipment, shackles and slings before use. Destroy any defective components as equipment merely discarded may be picked up and used by someone that is unaware of its defects. - Unsafe Equipment

Do not use equipment that is suspected to be unsafe or unsuitable. Any defect should be reported to a supervisor and suitability verified by a competent person. - Hazardous Wind Conditions

Never carry out any hoisting or rigging operations when winds create hazards for workers, the general public, property, materials or equipment. Assess load size and shape to determine whether high winds may cause problems. In particular, avoid handling loads with large wind-catching surfaces that may cause load to swing or rotate. Even though the weight of the load may be within the normal capacity of the equipment, high or gusting winds may prevent proper control during the lift. Wind can be critical to how the load is rigged, lifted, and landed, with consequences for the safety of everyone involved. When winds reach 40-48 km/h (25-30 mph), consider limiting hoisting operations. - Hazardous Weather Conditions

When the visibility of riggers or hoist crew is impaired by snow, fog, rain, darkness, or dust, strict supervision must be exercised and, if necessary, the lift should be suspended. At sub-freezing temperatures, you must ensure that no part of the hoisting device is shock- loaded or impacted, since brittle fracture of the steel may result. - Electrical Contact

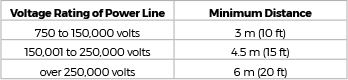

One of the most frequent killers of riggers is electrocution caused by the contact of hoisting device, load line, or load with power lines. Be especially careful when working near overhead lines that have long spans. These lines tend to swing laterally in the wind and can cause unexpected contact. When working with or around cranes that are within a boom’s length of any powerline, ensure that a competent signaller is stationed at all times within view of the operator to warn when any part of the machine or its load approaches the minimum distances specified in the table below.

Beware that wind can blow powerlines, hoist lines or the load and may cause them to cross into the minimum distance. Always know the line.

- Hoist Line Not Plumb

The working load limits of hoisting equipment apply only to freely-suspended loads on plumb hoist lines. If the hoist line is not plumb during load handling, side loads are created which can destabilize the equipment and cause structural failure with little warning.

1.8.1.2 Factors that Reduce Capacity

The safe working loads of all hoisting and rigging equipment are based on almost ideal conditions that are seldom given in the field. Riggers must therefore recognize the factors that can reduce the capacity of equipment.

- Swing

The swinging of suspended loads subjects the equipment to additional stresses that can cause tip-over of the crane or failure of hoisting hardware. The force of the swinging action makes the load drift away from the machine, increasing the radius and side- loading the equipment. The load must always be kept directly below the boom point or upper load block. - Condition of Equipment

The rated working load limits apply to equipment and hardware that is in good condition. Any damage equipment should be taken out of service and repaired or destroyed. - Weight of Tackle

The rated load limited of hoisting equipment does not account for the additional weight of hooks, slings, beam and other parts of the lifting tackle. The combined weight of these components must be added to the total weight of the load. The capacity of the hoisting equipment must be large enough for the additional load to be safely lifted.