On-Site Storage

Panels stored on-site should be protected from standing water, which can stain or discolour paint finishes and naturally weathering metals. If water does come in contact with stored panels, the panels should be sloped so that one end is higher than the other, which will allow water to drain off.

Hoisting Panels

The way that roof panels are hoisted to the point of installation is an important consideration for the installer. The panels should be supported along their length so that the stack or individual panel won’t bend significantly or kink, as a kink may render metal panels unusable.

Underlayment and Slip Sheets

On applications over solid substrate, an underlayment and slip sheet are recommended as a secondary barrier against water penetration and to protect the back side of the panels from the substrate. A slip sheet also protects against condensation that forms on the back of metal sheets.

Underlayment should be a minimum of one ply #30 asphalt-saturated felt as under all architectural metal roof systems. One layer of rosin sheathing paper or other slip sheet material should be applied over the underlayment where bonding of the metal panel to the felt underlayment may be a possibility. In addition to the felt underlayment, an eave protection and ice dam protection membrane at down slope perimeters, valleys, and around penetrations is recommended.

Expansion/Contraction

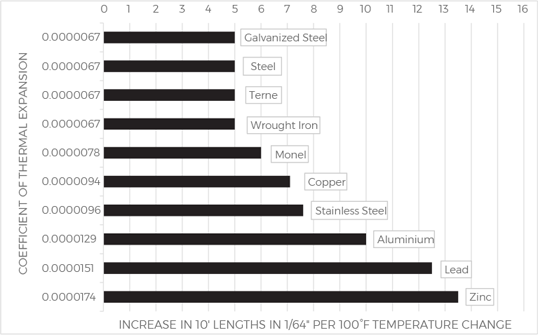

The expansion and contraction of metal that takes place with temperature changes can cause many problems for metal roofs if it is not considered by the designer. Expansion and contraction can cause flashings to become distorted and loose. Expansion and contraction not correctly allowed for can cause leaks and make the roof more vulnerable to storm and wind damage. Metal materials will move differentially with temperature change for one of the following reasons:

- Different materials have different coefficients of expansion.

- Some components may be exposed to a greater degree of temperature change than others (e.g., the exterior panels will have a greater temperature range exposure than the interior structure to which attachment is made).

- Movement of two materials is actually in different directions (e.g., long panel lengths must be accommodated by ridge-to-eave movement, while horizontal movement is more pronounced with ridge flashings).

Oil-Canning

A potential aesthetic problem for metal roofing is oil-canning. Oil-canning is a term that refers to distortions in the flatness of the metal. Oil canning is an aesthetic phenomenon that does not affect the performance of metal roof panels. Oil canning is more noticeable with highly reflective and bright finishes. Oil canning results from the presence of residual stresses in metal panels. The stresses may be introduced during coils production, panel roll forming, panel fastening or panel placement over uneven substrates or misalignment of clips used for panel attachment. There are several precautions that can be taken to reduce oil-canning. One is to use thicker metal, because thicker metal tends to oil-can less than thinner metal. Specifying metal panels with stiffening ribs in the pan of the panel helps to control oil-canning.

Slope Considerations

Most architectural metal roof panel systems are designed for a minimum 1:4 (25%) slope. As the slope of the roof decreases, the need to increase seam height with the addition of seam sealant or sealant tape (e.g., butyl) increases, below 1:4 requires a machine or mechanically seamed standing seam.

Roof and Metal Panel Layout

Prior to the installation of metal roofing panels, the roofer must decide how the panels are to be laid out on the roof. On highly visible roof areas, it is generally preferred to balance the width of the panels at each end of a roof section. On low-slope roof applications, or on roof areas where a rake or wall detail exists at one end and a hip or valley condition exists at the other end, there is generally no need to balance the panels. At hips and valleys, it is generally preferable to match up the seams at the point of intersection.

Roof Layouts

When appearance is important, it may be necessary to make a panel layout sketch, or mark on a roof plan, before installation begins. A layout plan can help to verify the correct panel size and the number of panels that will be required for the job.

Fastening

Panels are typically secured to the deck with hold-down clips (concealed) or exposed fasteners. The spacing of the fasteners depends on the gauge and type of panel. However, the panel is fastened, care must be taken to drive the fasteners straight and not to under or over tighten them. Misaligned fasteners can cause excessive wear or leakage at the fastening point.

Panels are typically secured to the deck with hold-down clips (concealed) or exposed fasteners. The spacing of the fasteners depends on the gauge and type of panel. However, the panel is fastened, care must be taken to drive the fasteners straight and not to under or over tighten them. Misaligned fasteners can cause excessive wear or leakage at the fastening point.