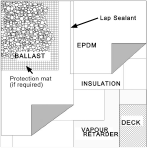

In loose-laid ballasted systems, the membrane is rolled out loose over the substrate with the membrane being held in place by a covering of ballast which typically consists of 19 mm to 38 mm (¾ to 1 ½ in) nominal sized round river washed stone. Crushed gravel (25 mm (1 in) clear or greater) can also be used as ballast, but a protection mat must be put down over the membrane prior to placing the gravel ballast to prevent damage to the membrane from any punctures. Ballast stone should meet the membrane manufacturers requirements for the desired wind uplift resistance with regard to size and coverage rates. It is typically required that stone ballast meet the requirements of ASTM D448 size 4, 357 or 3, with larger stone size required for heavier coverage rates. Concrete pavers can also be used instead of gravel ballast.

Although, the ballast holds the membrane in place, the membrane must be mechanically attached, usually with plastic or metal batten bars, at the perimeters of the roof and around roof penetrations with appropriate, approved fastening systems.

On most loose-laid ballasted roofs, the stone ballast is applied at a rate of approximately 60 kg/m2 (1200 lb square). In regions of high wind, additional ballast or other additional securement methods may be required for all or portions of the roof area. Because the materials are loosely laid, slope is an important factor. Loose-laid systems are typically limited to slope rates of less than 1:25 or (4%).

On most loose-laid ballasted roofs, the stone ballast is applied at a rate of approximately 60 kg/m2 (1200 lb square). In regions of high wind, additional ballast or other additional securement methods may be required for all or portions of the roof area. Because the materials are loosely laid, slope is an important factor. Loose-laid systems are typically limited to slope rates of less than 1:25 or (4%).