Blistering in Built -Up Roofs

46 – July 1996

Blistering is a common problem with field applied exterior coatings such as paints and built-up roofing systems. In built-up roofs blisters are raised surface areas over voids in a roof system which contain entrapped air and/or moisture. As the roof surface temperature rises the pressure inside the blisters rises and the adhesion of asphalt weakens. Blisters are usually noticeable on hot and sunny days, they range from small spongy spots to large pronounced areas. Leakage does not normally occur promptly, and even large blisters may continue for years without leaking 1. A roof often has many small blisters, not easily seen under the aggregate surfacing, which are better left alone. Large blisters should be repaired if the protective coating or gravel surfacing has slumped off exposing the bare felts.

Blisters develop from voids built into the roof. It has been demonstrated that a perfect void-free roof cannot be laid even under ideal conditions 2. Voids can result from skips in bitumen mopping, entrapped debris, curled felts, uneven gases and bitumen bubbling.

One misconception about blisters is that they are perfectly sealed. If this were the case blisters would never grow beyond the limits dictated by the gas content in the blister and the maximum surface temperature of the roof. Blistering of built-up roofing takes two main forms:

- blisters between the roof membrane and the substrate;

- blisters between the membrane plies.

BLISTERS BETWEEN THE ROOF MEMBRANE AND THE SUBSTRATE

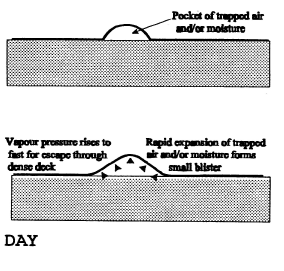

Blistering arises when pockets of air and moisture, trapped between the membrane and substrate, expand in the sudden heat of the sun and displace the membrane to form a small blister. The blister will only be formed when the substrate material has low permeability; under these circumstances temperatures from the heat of the sun can rise too quickly for trapped air and water vapour to escape through the substrate.

Blistering arises when pockets of air and moisture, trapped between the membrane and substrate, expand in the sudden heat of the sun and displace the membrane to form a small blister. The blister will only be formed when the substrate material has low permeability; under these circumstances temperatures from the heat of the sun can rise too quickly for trapped air and water vapour to escape through the substrate.

Blisters develop at a time of high roofing temperature. Bitumens, especially those with low softening points lose

their strength rapidly at temperatures above 601C at the time when the pressure in the pocket is highest. Pressures will then develop in the air pockets and this can cause a displacement and stretching of the roof membrane producing an increase in the size of the air pocket/blister. As the size increases, the pressure required to continue the growth may actually diminish since the total lift increases with the area lifted and the anchorage at the rim of the blister is proportional to the length of that line.

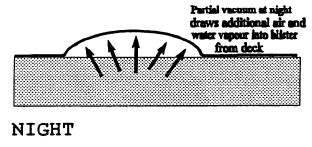

Therefore, for a small circular blister containing a given pressure, the lift per millimetre at its rim doubles when its diameter is doubled. Growth will contine until the anchorage greatly improves or the internal pressure drops. If the roof membrane has suffered an irreversible stretch, subsequent cooling will not cause the air pocket to return to the original size and a partial vacuum will occur in the now partly developed blister. Air and/or water vapour may be drawn slowly through the substrate to refill the original pocket, now slightly increased in size and ready to start another cycle of development of the blister when the sun appears again.

Therefore, for a small circular blister containing a given pressure, the lift per millimetre at its rim doubles when its diameter is doubled. Growth will contine until the anchorage greatly improves or the internal pressure drops. If the roof membrane has suffered an irreversible stretch, subsequent cooling will not cause the air pocket to return to the original size and a partial vacuum will occur in the now partly developed blister. Air and/or water vapour may be drawn slowly through the substrate to refill the original pocket, now slightly increased in size and ready to start another cycle of development of the blister when the sun appears again.

It has been reported that there is an increased propensity for blister formation when built-up roof membranes are applied directly to cellular foam insulations. This increase in blister occurrence was initially thought to be due to gases escaping from the cells of these insulations. Although there is little evidence for this, it is clear that the certain characteristics of these insulations may contribute to blistering. The impermeable nature of cellular foam insulations can increase blistering due to their inability to vent gases both during and after roof application. Many of these materials are suceptible to crushing, deformation, and/or facer delamination during application. In addition, some insulations are heat sensitive making the application of the membrane to them in hot asphalt difficult, often resulting in poor attachment and numerous voids. To avoid the problems associated with the use of these materials under built-up roofing membranes the CRCA strongly recommends they be overlayed with a layer wood fibre, glass fibre, perlite or other suitable coverboard material 3.

BLISTERING BETWEEN MEMBRANE PLIES

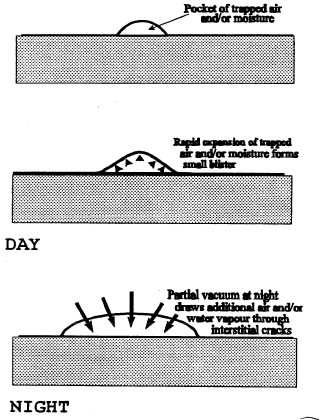

The traditional concept of inter-layer blistering assumes that the blisters are caused by air and moisture trapped between the layers during application. In reality, substantial blisters cannot form without a topping-up process to add more air and moisture between the layers. Measured pressure levels measured inside blisters are less than those expected form sealed systems, and it is clear that blisters inhale and exhale daily.

The traditional concept of inter-layer blistering assumes that the blisters are caused by air and moisture trapped between the layers during application. In reality, substantial blisters cannot form without a topping-up process to add more air and moisture between the layers. Measured pressure levels measured inside blisters are less than those expected form sealed systems, and it is clear that blisters inhale and exhale daily.

In a perfectly closed and elastic system a void within a roof will grow due to the expansion of air and/or water vapour by day, but it will subside to its original dimensions at night. Built-up roofing membranes are not perfectly elastic, they expand easily when they are warm but become stiff and resist returning to their original shape when they are cooled. Any permanent deformation of the membrane will create a vacuum within the blister and air will find its way into the enclosed space through microscopic cracks in bitumen moppings or along the felts themselves.

Blisters grow when:

- the volume of air sucked into them at night exceeds the volume of air forced out of them by day, and this increased pressure overcomes the peripheral bond of the blister.

- Blisters are initiated by voids built into the roofing system but, even in perfect conditions, a few small voids are inevitable in built-up roofing applications. A few small voids do no pose a problem with respect to membrane blistering as membrane elasticity and adhesion can accommodate small movements. However, numerous large voids will result in membrane blistering problems. The roofing contractor can reduce the likelihood of blistering by following standards of good practice which include installing dry materials in weather conditions suitable for roofing and on dry substrates. Winter conditions may require special precautions as days a shorter, the air is cooler, and the asphalt will cool more rapidly. Installing a suitable overlay board over cellular foam insulations and ensuring intimate contact between all the roofing materials will decrease the likelihood of voids promoting blister formation from occurring.

Treatment of blisters

If a few small blisters develop, they often do not result in problems, provided they remain watertight and do not become too large. Eroded bare spots on small blisters can be coated with a cold-process asphalt coating and sprinkled with gravel. If a blister approaches a dimension of about 600 mm (2 ft.), it is recommended that its outer boundary be marked so that it can be checked periodically to determine if it is getting larger. When blisters grow to about 1.5 m (5 ft.), or if they occur in a high traffic area, blisters should probably be repaired. To avoid breaking blisters, people on the roofs should try not to step on them, particularly when the membrane is cold.

If a blister is broken or otherwise capable of taking in water, the usual repair process is to remove the entire raised portion of the blister and patch the remaining void with alternate layers of asphalt and successively larger pieces of felt. Alternately, an “X” can be cut into the blister, the corners of the cut peeled back into the bitumen. The blister would then be patched as before.

As an alternative to traditional repair methods, contractors should consider employing specially designed vents developed by the U.S. Army Cold Regions Research and Engineering Laboratory. These vents, which allow for a quick repair, are available commercially 4.

___________

References

- Joy, F.A., “Premature Failure of Built-up Roofing, Pennsylvania State University, University Park, Pennsylvania, September (1963).

- Cullen, W.C., “The Perfect Roof: Can It Be Built?”, Roofing ’87, NRCA, (1987).

- “Fibreboard Overlays”, CRCA bulletin, March (1993).

- Korhonen, C & B. Charest, “Roof Blister, Cause & Cure”, US Army Corps of Engineers, Cold Regions Research & Engineering Laboratory, Report 95-19, July (1985).

The opinions expressed herein are those of the CRCA National Technical Committee. This Technical Bulletin is circulated for the purpose of bringing roofing information to the attention of the reader. The data, commentary, opinions and conclusions, if any, are not intended to provide the reader with conclusive technical advice and the reader should not act only on the roofing information contained in this Technical Bulletin without seeking specific professional, engineering or architectural advice. Neither the CRCA nor any of its officers, directors, members or employees assume any responsibility for any of the roofing information contained herein or the consequences of any interpretation which the reader may take from such information.