Ballast For Protected Membrane Roofing

35 – June 1988

The Protected Membrane Roofing (PMR) has evolved considerably during the past twenty years and some of the changes involve the design of the ballast required to maintain the system in place.

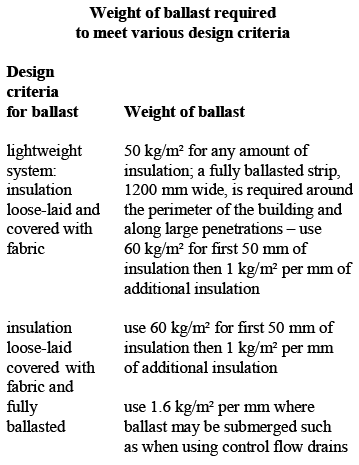

Initially the insulation was adhered to the membrane with hot asphalt and the practice was to apply enough ballast to counteract the buoyancy effect of the water covering the insulation in case of ponding. The weight was taken to be equal to the amount of water displaced by the insulation or 1 kg/m² per mm of insulation. Since the insulation also had to be protected from ultra-violet (UV) degradation, the minimum weight of stone required to achieve coverage was set at 60 kg/m². This coverage was thus the minimum quantity recommended for up to 50 mm of insulation. Beyond the 50 mm thickness the amount of ballast had to be increased at the rate of 1 kg/m² per mm of insulation.

With the advent of higher energy costs and the use of thicker insulation, the proponents of the PMR proposed the installation of a lightweight system. The insulation would be loose-laid (free of float) but covered with a fabric which would keep the insulation boards in their respective position, in case of flotation. Ballast would be applied at the rate of 50 kg/m², regardless of the amount of insulation used. the system requires a 1200 mm wide strip of gravel applied at the rate of 1 kg/m² per mm of insulation (60 kg/m² minimum for up to 50 mm) around the perimeter to prevent the insulation from floating. Similar protection should be used at large penetrations in the roof. As long as the fabric is UV resistant and the manufacturer will guarantee that it will not deteriorate if exposed to the weather, there is no need to fully cover the fabric with gravel.

Some designers now specify a fully ballasted system with loose-laid insulation covered with a fabric. In this case the insulation and fabric are installed as in the lightweight system but the weight of ballast is calculated on the basis of 1 kg/m² per mm of insulation. Minimum weight of ballast required is 60 kg/m² for the first 50 mm.

Where a fully ballasted system can become fully submerged such as on a roof where control flow drains are specified, the submerged gravel loses about one third of its weight and the minimum weight required to counteract the effect of buoyancy on both the insulation and the gravel is 1.6 kg/m² per mm of insulation.

A minimum slope of 2 percent is required when using the Protected Membrane Roofing.

Consult CRCA’s Roofing Specification Manual for Tolerances