All components and equipment of any fall protection system must be inspected for damage, wear and obvious defects by a competent worker before each use and on a regular basis. If any part of the system is found to be defective or damaged, the component MUST be removed immediately from service. Also, if a worker who is using the fall protection experiences a fall, the system shall be immediately removed from service and shall not be used again unless all components of the system have been certified by the manufacturer as being safe for re-use.

Any worker required to use fall protection must be trained in its safe use and proper maintenance.

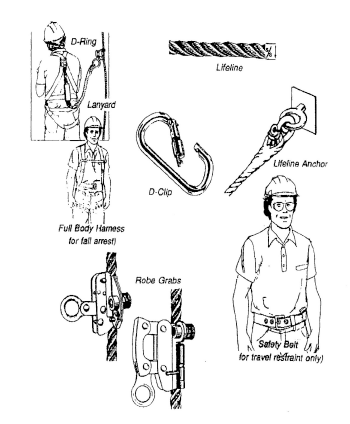

Harness

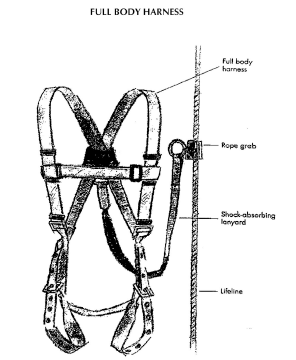

Full Body Harness

- Chest strap should be adjusted so that it’s snug and located near the middle of the chest. In a headfirst fall, a properly adjusted chest strap will prevent the worker from coming out of the harness.

- Leg straps should be adjusted so the worker’s fist can fit snugly between the strap and leg.

- Harness straps should be adjusted so that the D-ring is located between the shoulder blades. A properly positioned D-ring will keep a worker upright after fall arrest.

Safety harnesses must be CSA-certified and carry a CSA label. The harnesses must be adjusted to fit the individual worker and be worn with all hardware and straps intact and properly fastened.

Harnesses should ALWAYS be inspected before beginning of work and on a daily basis. When inspecting a harness or safety belt, one should look for the following:

- Loose, bent or missing rivets, grommets or buckles

- Loose, worn or broken stitching

- Frayed material

- Cracks or excessive wear in D-ring

- Signs of deterioration from contact with chemicals or petroleum products

- Cracks or excessive wear to buckle

- Burns, cuts or abrasions

- Brittleness caused by prolonged exposure to heat or sunlight

Any damaged equipment must be removed from use immediately and safely discarded.

Lanyard

A lanyard is a flexible strap that is attached to a worker’s harness at one end and to a lifeline or anchor point at the other end.

- Use manufactured lanyards only. They can be made of wire rope, synthetic fibre rope, or synthetic webbing.

- Lanyards are manufactured to specific lengths. Never try to shorten a lanyard by tying knots in it. Knots can seriously reduce its rated strength.

- Never store lanyards around chemicals, sharp objects, or in wet places.

- Never leave them exposed for long periods to direct sunlight.

Lanyards should be inspected before every use and on a regular basis. Inspect lanyards for

- Burns, cuts, or signs of chemical damage

- Loose or broken stitching

- Frayed web material.

Shock Absorbers

Shock absorbers absorb some of the force generated during fall arrest.

- One end of the shock absorber must be connected to the D-ring on the full body harness.

- In most cases the shock-absorbing component is enclosed in a snug-fitting cover jacket to protect it from the day-to-day activities. In a fall, the cover jacket tears open as the shock absorber deploys.

- Check the cover jacket for stress or tearing. Many shock absorbers have a tag on the cover jacket that tears if the shock absorber is exposed to a shock load. Make sure this tag is intact.

- Ensure that a shock absorber built into a lanyard has a constant cross-section or diameter.

- Shock absorbers can be purchased as separate equipment or built directly into lanyards.

Lifelines

A lifeline is a rope that is connected between one or more anchor points, to which a worker’s lanyard is attached to. There are three types of lifelines:

- Vertical

- Horizontal

- Retractable

All lifelines must be inspected daily and prior to each use to ensure that they are in good condition. A lifeline is considered unsafe and should be removed from use if you find any of the following:

- Cuts, burns, frayed strands, abrasions, and other defects or signs of damage

- Broken or loose strands

- Discolouration and brittleness indicating heat or chemical exposure

Ensure that rope grab is compatible with type of lifeline rope that is being used. Protect lifeline from any rough or sharp edges.

Vertical Lifelines

A vertical lifeline extends to the ground or has a positive stop that prevents a worker’s rope grab from running off the end of the lifeline.

Vertical lifelines must comply with the current edition of the applicable CSA standard CSA Z259.2.5 Fall Arresters and Vertical Lifelines and the following minimum requirements:

- Only one person at a time may use a vertical lifeline.

- Vertical lifeline must reach the ground or a level above ground where the worker can safely exit or must have a positive stop to prevent the rope grab from running off the end of the lifeline.

Vertical lifelines are typically 15.9 mm (5/8 in) synthetic rope (polypropylene blends).

Horizontal Lifelines

A horizontal lifeline extends between two anchor points which restricts a worker’s horizontal movement on a roof and prevents them from reaching an area where they could fall.

A horizontal lifeline consists of a synthetic or wire rope, or fixed rail, rigged between two substantial anchor points. Lifeline systems allow the worker to move horizontally along the work surface while being connected to the lifeline.

A horizontal lifeline system must be designed by a professional engineer. The design can be a standard design or specifically engineered for a particular work site.

The design for a horizontal lifeline system must:

- Clearly indicate how the system is to be arranged, including how and where it is to be anchored.

- List and specify all required components.

- Clearly state the number of workers that can safely be attached to the lifeline at one time.

- State instructions for installation, inspection, and maintenance.

- Specify all of the design loads used to design the system.

The system must be installed, inspected, and maintained in accordance with the professional engineer’s design requirements. A complete and current copy of the design must be kept on site as long as the system is in use.

Regulations require that “a horizontal or vertical lifeline shall be kept free from splices or knots, except knots used to connect it to a fixed support.” Knots along the length of either a horizontal or vertical lifeline can reduce its strength by as much as 40%.

Retractable Lifelines

Retractable lifelines consist of a lifeline spooled on a retracting device attached to adequate anchorage.

- Retractable lifelines must comply with CAN/CSA Z259.2.2 Self-Retracting Devices for Personal Fall-Arrest Systems.

- Retractable lifelines are designed to be anchored above the worker and are not generally recommended for use in roof work.

- The lifelines employ a locking mechanism that lets the line unwind off the drum under the slight tension caused by a worker’s normal movements and then automatically retract when tension is removed, thereby preventing slack in the line. The lifeline locks up when a quick movement, such as that caused by a fall, is applied.

- The lifelines are designed to minimize fall distance and the forces exerted on a worker’s body by fall arrest.

- Refer to the manufacturer’s instructions regarding use, including whether a shock absorber is recommended with the system.

Any retractable lifeline involved in a fall arrest must be removed from service until the manufacturer or a qualified testing company has certified it for reuse.

Lifeline Hazards

The following are hazards that a lifeline may be exposed to. Ensure that material being used for lifeline is resistant to these hazards that could damage the lifeline or provide appropriate protection.

Ultraviolet light – Exposure to the sun may damage or weaken synthetic lifelines.

Temperature – Extreme heat can weaken or damage some lifelines while extreme cold can make others brittle.

Friction and abrasion – Normal movement may wear, abrade, or otherwise damage lifelines in contact with sharp or rough surfaces. Protection such as wood softeners or rubber mats can be used at contact points to prevent wear and tear.

Sparks or flame – Hot work such as welding or flame cutting can burn, melt, cut, or otherwise damage a lifeline.

Chemicals – Chemical exposure can burn or degrade a lifeline very quickly.

Storage – Always store lifelines separately. Never store them where they may contact hazards such as sharp objects, chemicals, or gasoline.

Rope Grab

A rope grab is device that is attached to a lanyard and lifeline. The rope grab moves along the lifeline and will lock in the event of a fall. It will remain locked on the lifeline until the applied force is released. Each rope grab is designed and manufactured for use with a specific diameter and type of lifeline. The rope grab and lifeline that is used must be compatible. Consult manufacturer instructions for compatibility.

The rope grab must also be attached to the lifeline in the correct direction—not upside down. On most rope grabs an arrow indicates the direction in which to orient the device. In addition, each rope grab is designed for use with a specific length of lanyard, normally 600 to 900 mm (2 to 3 ft) maximum.

Connecting Devices

Locking Snap Hook has a spring-loaded keeper across the opening of the hook that cannot be opened unless the locking mechanism is depressed.

Karabiner (D-Clip) is designed not to open under twist loads. To open the gate or keeper requires two separate actions: 1) twisting the locking mechanism and (2) pulling the locking mechanism back. When released, the spring-loaded locking mechanism flicks back into the locked position.

Check all connecting devices for:

- Damage, cracking, dents, bends, or signs of deformation

- Connecting rings centered—not bent to one side or otherwise deformed

- Rust

- Moving parts working smoothly

- Signs of wear or metal fatigue